Enterprise

Qualcomm reportedly urged US to reverse the Huawei ban

Out with Kirin, in with Snapdragon?

Yesterday, Huawei confirmed the inevitable end of the Kirin chip, owing to the heightening American ban. When it launches later this year, the Huawei Mate 40 series is the last phone to feature the iconic processor. Despite the terrible news, Huawei’s fate is still up in the air. For one, the Trump administration can still (unlikely) reverse everything, restoring Huawei’s former status on top of the industry. In another likelier scenario, a third-party chip supplier can provide some much-needed supply for the ailing Chinese company. Today, Qualcomm reportedly urged US to reverse the Huawei ban.

It’s still a shocking plot twist. Qualcomm has clashed with the Chinese company in the processor industry before. Naturally, when the bans rocked the smartphone industry, the company’s continued dominance flourished at the rival’s major losses. However, Qualcomm CEO Steve Mollenkopf soon announced long-term pursuits to court Huawei’s business. The supposed courting fell silent just as quickly.

Today, however, the Wall Street Journal has leaked a presentation detailing Qualcomm’s lobbying to reverse the ban. According to the document, the chip-making company wants to lift exporting restrictions so it can sell its chips to Huawei. With the export ban in place, the US will allegedly drive Huawei’s business away from America and into competitors from other countries like Samsung and Mediatek.

Of course, it’s also important to note that this is different from an operating license. Amidst the ban, a few American companies have applied for a license to sell components to Huawei. Qualcomm has not applied for such a license — at least, not yet. Instead, the company wants every export restriction lifted, allowing other companies to also do business with Huawei.

Lobbying is only one thing. It’s still up to the US government, ultimately. However, American companies are also fighting the extensive ban. Only time will tell if things will go back to how they were.

SEE ALSO: Mate 40 is the last Huawei phone to feature Kirin chips

Enterprise

Mutant launches 2026 playbook to guide brands on earning credibility

The new ‘Make It Make Sense’ report reveals how Southeast Asian brands can build credibility in small, authentic spaces.

Mutant has launched its 2026 regional playbook, Make It Make Sense, a guide designed to help PR, content, social, brand, and influence teams strengthen credibility in a rapidly shifting communications environment across Southeast Asia.

The report outlines the growing challenge for brands operating in the Philippines, where the competition has shifted from gaining attention to earning trust.

Mutant notes that national conversations are increasingly shaped by micro-communities on TikTok, Facebook Groups, and private messaging platforms.

These smaller spaces have become central to building belief, as Filipino audiences grow more selective about which voices they consider authentic.

This trend reflects broader behavioural shifts across the region. With algorithms driving how information spreads, awareness has become easy to achieve, while credibility has become more difficult to secure.

Mutant’s 2026 playbook explores how brands can stay relevant and culturally grounded while navigating fragmented digital ecosystems.

The guide breaks down several key areas: the rise of believability as a competitive advantage; approaches to managing algorithm-driven social platforms; the growing importance of cultural fluency in PR; the need for clarity and consistency in content strategy; the influence of authentic micro-communities; and how brands can balance regional ambitions with local insights.

For companies in the Philippines, Mutant emphasizes that long-term brand strength will come from credibility built through culture, communities, and everyday behaviour rather than through visibility alone.

The full Make It Make Sense playbook is available for download on Mutant’s website. Media inquiries, interview requests, and expert commentary are available through [email protected].

Enterprise

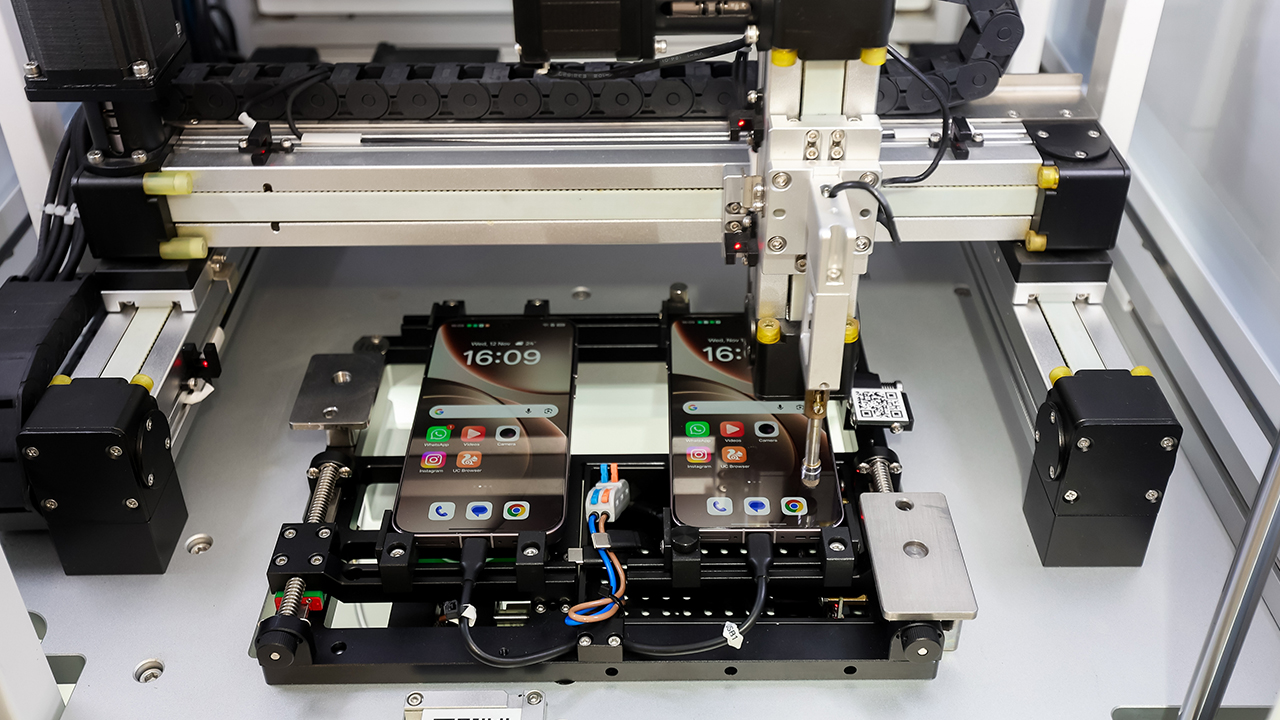

A closer look at Apex Guard and the world behind OPPO’s quality promise

I went inside Binhai Bay to see how OPPO is building its next chapter of smartphone quality.

OPPO introduced Apex Guard, a full technology suite designed to protect the user experience with stronger hardware and smarter software.

The new concept shows how OPPO is redefining smartphone quality by focusing on long-term reliability and dependability, and a user journey that stays smooth for years.

I saw this vision firsthand during an exclusive behind-the-scenes visit to the Binhai Bay Campus, OPPO’s global headquarters and R&D hub.

The moment I stepped inside, I understood how deeply this company values the idea of quality. Every corner of the campus felt intentional. Engineers tested materials behind glass panels and the machines ran stress simulations.

Rooms were dedicated to design exploration and long-term validation. Walking through its corridors felt like moving through the inner workings of a promise.

OPPO builds quality into a device long before it becomes a device.

OPPO’s next step toward elevated quality

Apex Guard reflects OPPO’s goal of addressing real user needs with an end-to-end system that strengthens every part of a smartphone.

It reaches across all product lines and raises quality across three dimensions. OPPO focused on durability that protects users in unpredictable moments.

Through breakthroughs in materials and design, OPPO developed Ultra High Strength Steel and AM04 aerospace-grade aluminum alloy to withstand daily wear and heavier stress.

Armour Shield structural reinforcement adds another layer of protection that stays reliable even in unexpected situations like sudden drops or water exposure.

“The goal is simple: a device should feel solid in every scenario.”

Beyond the product lifespan

Apex Guard supports long-term reliability. One of the key innovations is the OPPO Silicon Carbon Battery with its customized spherical silicon-carbon material.

It improves long-lasting safety while extending battery life by up to 400 additional cycles. With this technology, OPPO devices stay closer to their original performance for a longer period, even after years of use.

OPPO also works with international testing organizations like TÜV Rheinland, TÜV SÜD, and SGS, and follows standards that exceed typical industry requirements.

Devices pass through multiple rounds of strict testing, including more than 180 assessments that begin before R&D and continue until the end of the product lifecycle. Even after-sales services follow a higher standard to ensure users feel supported beyond the purchase.

Rethinking quality through next-level software smoothness

Since smoothness is one of the most noticeable indicators of smartphone quality, OPPO made software a major part of Apex Guard.

In ColorOS 16, the All-New Luminous Rendering Engine brings the first Unified Animation Architecture on Android, creating consistent movement across the entire system.

Chip-Level Dynamic Frame Sync Technology helps the device react faster when multitasking, while Sensor Offload shifts critical sensor tasks to the SoC to reduce power consumption, especially when recording 4K 60fps video.

ColorOS 16 also introduces Instant Refresh to help reduce data fragmentation on entry-level devices. OPPO performs 48-, 60-, and 72-month aging tests to ensure long-term responsiveness.

The company developed new systems to measure smoothness more accurately, including the OPPO Smoothness Baseline Test and the industry-first Parallel Animation Standard 6 Zero, which evaluates lag, latency, flicker, crashes, mislaunches, and freezes.

These standards apply across the entire lineup, from A Series to Find Series.

At the home of OPPO quality

OPPO continues to expand the Binhai Bay Campus to support its vision for the future.

The campus brings together more advanced equipment, centralized teams, and specialized laboratories designed to test quality from every angle.

The Materials Lab studies long-term durability while the Intelligent Terminal Testing Lab pushes devices through real-world challenges.

Meanwhile, the Power Consumption Intelligent Lab evaluates energy efficiency, and the Communication Lab ensures strong connectivity.

Standing inside these spaces and watching the process unfold made the idea of next-level quality feel more real.

It is not a statement but a system built into every decision and test. Apex Guard is simply the name OPPO has given to the work it has been doing all along.

Enterprise

AgiBot robots can now learn skills on the factory floor

Robotics company deploys real-world reinforcement learning system

Robotics company AgiBot has successfully deployed its Real-World Reinforcement Learning (RW-RL) system on a pilot production line with Longcheer Technology.

The company specializes in embodied intelligence, and the project marks the first application of RW-RL in real industrial robotics.

It connects advanced AI innovation with large-scale production, signaling a new phase in the evolution of intelligent automation for precision manufacturing.

Precision manufacturing lines have long relied on rigid automation systems that demand complex fixture design, extensive tuning, and costly reconfiguration.

Where AgiBot’s RW-RL system comes in is addressing such pain points. It enables robots to learn and adapt directly on the factory floor.

Within just minutes, robots can acquire new skills, achieve stable deployment, and maintain long-term performance without degradation.

The system also autonomously compensates for common variations, such as part position and tolerance shifts

Meanwhile, during line changes or model transitions, only minimal adjustments and standardized deployment steps are required. This dramatically improves flexibility while cutting time and cost.

Moreover, AgiBot’s system allows for flexible reconfiguration. Task or product changes can be accommodated through fast retraining; such solution exhibits generality across workplace layouts and production lines.

This milestone signifies a deep integration between perception-decision intelligence and motion control. And it represents a critical step forward unifying algorithmic intelligence and physical execution.

Unlike many laboratory demonstrations, AgiBot’s system also achieved validation under near-production conditions. It has completed a full loop from cutting-edge research to industrial-grade verification.

Moving forward, AgiBot and Longcheer plan to extend real-world reinforcement learning to a broader range of scenarios. These include consumer electronics and automotive components, with focus on developing modular and rapidly deployable robot solutions.

-

Reviews2 weeks ago

Reviews2 weeks agorealme C85 5G review: Big battery, tough body

-

Reviews6 days ago

Reviews6 days agoPOCO F8 Pro review: Lightweight, heavy hitter

-

Cameras1 week ago

Cameras1 week agoDJI Osmo Action 6 review: An adventurer’s best friend

-

News2 weeks ago

News2 weeks agorealme C85 with 7000mAh battery, 5G connectivity officially launches

-

Reviews6 days ago

Reviews6 days agovivo X300 review: The point-and-shoot I’ll always carry

-

Reviews6 days ago

Reviews6 days agoPOCO Pad X1 review: A tablet that keeps up with your day

-

News6 days ago

News6 days agoPOCO F8 Series: Price, availability in PH

-

Drones7 days ago

Drones7 days agoDJI Neo 2 review: Fly without fear